Ensure a pleasant environment for everyone – Prevent complaints and safeguard your reputation with our expert odour removal services

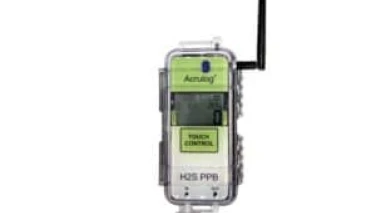

Using PCP’s Acrulog CEMS unit can measure the before and after from any filtration equipment and give early warning of failing equipment before any neighbourhood complaints.

The system is designed to incorporate auto dosing at a corporate level to ensure maximum suppression of odours using minimal quantities of additives. Additives are available in multiple supply and storage configurations.

Yes — mobile trailer units are available for rapid deployment.

Yes, our Acrulog high-sensitivity PPB H2S logger will provide accurate and trended data to enable you to determine your levels.

Yes — perimeter fogging and mobile units are easy installed and modified to suit individual applications. Mobile units provide a flexible solution where water and power aren’t available and where rapid deployment is required.

Yes — Installing our solutions will ensure that odour complaints are kept to a minimum to prevent intervention by local authority.

Absolutely, – we offer equipment and solutions monitoring control we would be happy to recommend our accredited labs to provide data for reporting.

Yes — fogging and dosing systems can complement existing odour treatment infrastructure, giving an extra layer of control during high-load periods.

Yes — monitoring and reporting tools provide audit-ready data.

Yes – all products are fully biodegradable, non-toxic, and safe for use around water, soil, and sensitive biological processes like anaerobic digestion.

Yes — we supply technical data sheets, case studies, and system performance evidence to support permit applications and environmental management plans.

A combination and high-pressure fogging systems and low-pressure fogging systems combined with dosing systems can form part of a comprehensive odour control strategy.

Yes — Our tech produces droplets that are suitably sized to ensure that they don’t saturate the air and wet the ground surface.

Yes — some agents can be dual-purpose, tackling both.

Yes — units can be sensor-triggered, timer-based and door-activated to match activity.

No — they operate in parallel without affecting throughout.

Yes — mobile trailer units are available for fast deployment.

Yes — odour control at source significantly cuts drift off-site.

Yes — additives are biodegradable and non-disruptive to biological processes.

Yes — Odour suppression can be used on the outfeed of most odour control equipment.

Yes — we provide cloud-based reporting.

Yes — dosing can be scaled up in warmer months.

No — they are non-corrosive and safe for plant machinery.

We hold a comprehensive range of replacement pumps for quick turnaround , however should we not have your particular pump, through our partnering network, we would look to source and replace your pump for you asap saving you time and stress.

Yes, if needed.

Yes — they operate automatically with minimal intervention.

No — they use water pressure and pumps only.

Yes — we provide CAD/BIM models for design inclusion.

Minimal — systems are modular and quick to install.

Yes — full handover documentation is provided.

Yes — full civils/electrical specs are supplied.

Yes — integration with control systems is standard.

Yes — dosing capacity and fogging networks can expand.

It reduces complaints and shows commitment to ESG goals.

Yes — we have many case studies across Ireland.

No — running costs are low, with occasional additive refills.

Yes — full SLAs and on-call support available.

We have a full range of odour solutions available for more information

Yes — mobile cannons and fogging trailers can be redeployed quickly with their own power and water supply.

Compact fogging lines protect silos, while cannons handle open-air stockpiles.

Yes — our agents are food-safe, non-toxic, and compliant with agri-feed standards.

Yes — fogging activates automatically with conveyor or loader start-up.

Yes — suppression keeps odour levels within regulatory limits.

Yes — all products are biodegradable, non-toxic, and water-safe.

Yes — we supply technical specs, case studies, and monitoring reports.

Yes — monitoring tools provide audit-ready evidence.

By applying suppression at unloading and boundaries, odour drift is minimised.

Yes — systems can be timer or sensor controlled for efficiency.

No — our systems run without slowing operations.

No — fine mist and neutralisers are designed to avoid wetting or contamination.

Yes — cloud integration allows off-site system monitoring.

Yes — centralised control allows you to manage multiple systems easily.

Yes — modular systems expand as throughput increases.

Yes — we offer flexible hire for seasonal or one-off shipments.

Yes — it reduces exposure to strong odours and improves air quality.

Yes — designed in line with occupational exposure guidelines.

Yes — they are non-toxic and approved for occupational safety.

Yes — we deliver toolbox talks and handover training.

Minimal — periodic nozzle cleaning and filter checks.

Yes — they align with routine port servicing cycles.

Yes — systems operate on mains or generator power.

Yes — PCP stocks spares locally for quick turnaround.

Modular design means quick swap-outs with minimal disruption.

No — components are stainless steel and corrosion resistant.

PCP fogging systems are designed to run in the background, targeting odour hotspots without interfering with workflow.

Yes — they can be triggered by process controls or sensors to match production schedules.

Yes — fogging neutralises odours from blood, offal, fishmeal, or organic waste.

Yes — our agents are food-safe, non-toxic, and meet HACCP/BRC requirements.

No — compact designs fit neatly into production halls or waste areas.

Yes — we handle design, installation, commissioning, and training.

No — agents are applied in controlled areas away from product lines and are food-safe.

Yes — odours are neutralised, making processing areas safer and more comfortable.

Yes — all systems come with tailored RAMS and O&M manuals.

Yes — fully compliant with food industry certifications.

Yes — we provide full documentation and validation reports for auditors.

Yes — suppression can be zoned to specific high-risk areas.

Yes — PCP suppression systems keep odour levels within licence limits.

Yes — fully biodegradable and non-toxic.

Yes — technical specs and case studies are supplied.

Yes — monitoring tools provide audit-ready data.

Yes — dosing can be increased during high-load periods.

Yes — systems can run automatically based on sensor triggers.

No — they require simple checks and cleaning every few weeks.

Yes — training is provided for routine checks and servicing.

Yes — systems connect to existing water/power lines or run standalone.

No — all agents are non-corrosive and equipment uses stainless components.

Systems include filters, and nozzle design ensures quick and simple repairs by hand without the need for tools.

Yes — full maintenance and support contracts are available.

Our Miniat atomisers and cannons neutralise odours directly at the waste face, where emissions are strongest.

No — systems operate independently of compactors and covering equipment.

Yes — mobile systems can be on-site within 24–48 hours.

Yes — mobile trailer cannons and fogging units can be redeployed quickly.

Yes — dosing can be increased manually or via automated triggers.

Yes — we provide toolbox talks and full operator training.

Yes — boundary fogging captures odours before they drift off-site.

Yes — suppression can be paired with air monitoring for audit-ready reports.

Yes — technical specs, case studies, and system logs are available.

Yes — fogging complements existing gas extraction or biofilter systems.

Yes — all agents are biodegradable and safe for leachate areas.

Yes — dosing can be increased during high-odour periods.

Yes — fogging systems provide active control in real time, reassuring stakeholders.

Yes — all agents are non-toxic and safe for public exposure.

Mobile suppression can be deployed within days, often resolving issues before escalation.

Yes — boundary fogging and mobile units are ideal for entry points.

No — they require minimal upkeep, mainly filter checks and nozzle cleaning.

Yes — mobile and modular units move with site development.

Yes — PCP stocks critical parts locally for quick response.

Yes — systems can connect to mains or run standalone with generators.

Yes — full training for in-house servicing is included.

We are local specialists in Kildare, offering tailored environmental solutions to meet your specific needs.

Our Magnetic Hump and Round Pipe Separators provide a simple and effective way to remove tramp iron contamination from gravity or pneumatically conveyed, dry free flowing products such as feed, grain, wood ships, food stuffs, sand or plastic..

High pressure fogging lines provide the most effective method of odour suppression for boundary lines and tight locations.

The best solution for deodorising bad odours in any industry. Dry vapour, as it has similar properties to the gas it is treating, ensures maximum contact time for active chemistry to take place. This system can be used successfully for indoor and outdoor applications.

We supply a complete range of deodorising liquids to complement our range of solutions. Scented and unscented , vaporising liquid and odour suppression liquid additive to suit any application.

We provide sustainable solutions for managing air emissions from processing in waste water treatment, food processing and agriculture.

Together with Acrulog we are dedicated to working with utilities to overcome challenges of working in harsh environments and conditions.

The filters are designed to operate passively or with wind assisted fans, no water or power is required to operate efficiently. They can be adapted to fit most venting situations and are easily and quickly installed.

Our combined media filters absorb and treat the noxious gases in sewerage networks – there is no longer a need to work from heights, cranes or cherry pickers increasing site safety.

The ZC-Filters achieve up to 99.9% hydrogen sulphide (H2S) gas removal through adsorption, absorption and conversion of gaseous compounds. These systems can operated passively or with active extraction depending on the application.